IBC Tote Mixers for Commercial Construction

Liquid products and their role in commercial construction

The commercial construction industry is largely responsible for how the man-made features of our country look, function and last. Whether it’s the buildings in which we work, the roadways and mass transit infrastructure we travel, or the single and multi-family homes in which we live - construction contractors play a critical role in the quality of our daily lives.

While heavy materials, such as steel beams, formed concrete, lumber, and glass form the structural foundations of major building projects, liquid products also play an important role. They protect raw materials against the elements and improve the aesthetics of buildings and homes.

Functional liquid products used in construction include:

- Admixtures for improving concrete physical properties

- Asphalt cements and emulsions

- Traditional paint and coating products

- Pigments that produce the growing variety of mulch colors used in modern landscaping

Each of these product types and countless others like them are originally blended in a variety of batch sizes and mixing processes. A mixing tank, such as INDCO’s SST-800, an 800-gallon stainless steel mixing tank with a top mounted industrial mixer is a typical batch production setup.

Distribution, storage, and mixing of liquid products

Following the original production process, these products are distributed to the field for storage and use on or near a job site. Intermediate bulk containers, or IBC totes, are common containers for transportation and use on site due to their cubic shape and integral shipping pallet base design convenient for movement with a forklift.

The most common volume of an IBC Tote Mixer is 275-gallons - although they are available in other capacities. You can gain access to the products stored in the totes via a 6” diameter plastic screw cap at the center of the tote’s top surface. Some products can be pumped directly from the tote for use. Others, however, are not suitable for immediate use due to product quality degradation resulting from storage.

Best mixers for on-site mixing

Suspended solids often settle, and emulsion components can stratify such that the originally homogeneous product quality is lost. To restore liquid products to their original quality, distributors and on-site contractors utilize portable mixers. For IBC totes specifically - there are multiple designs that can be utilized. Selection is based on product properties, such as density and viscosity, as well as the degree of agitation required to produce the required results.

The most economical tote mixer product is one that features a drive motor, mixing shaft, and mixing impeller built directly into a 6” tote cap. The IBC tote mixer is installed by simply removing the existing cap and screwing on the one with the integrated mixer. One such model is the INDCO model TL-11A, an economical air powered mixer suitable for the lightest liquids and lowest viscosities, such as those that are somewhat “water-like”.

The TL-11A, or the TL -050T if an electric model is desired, are great options for liquid asphalt cements, concrete admixtures, contractor grade paints, and dyes for mulch as they will provide the mild agitation to restore the desired consistency of these light liquids. Higher powered models are available for more intense agitation and bracket mounted models, such as the BT-11T, for added stability of a steel mounting bracket that spans the top of the tote.

Mixing liquids with high density, high viscosity, or solids content.

For mixing liquid formulations with higher density, solids content, or overall viscosity, using a mixer with greater horsepower and torque is recommended, especially in totes as the cubic shape is great for shipping but much less optimal for mixing. Commercial coatings designed for protection against the elements and corrosion are examples of products with more demanding fluid properties.

These products range from water-based formulations with solids to viscous epoxies and urethanes, all of which benefit from multiple larger diameters mixing impellers versus one for lighter liquids. Mixing impellers for these applications fold open to maximize the impeller diameter once installed through the six-inch opening.

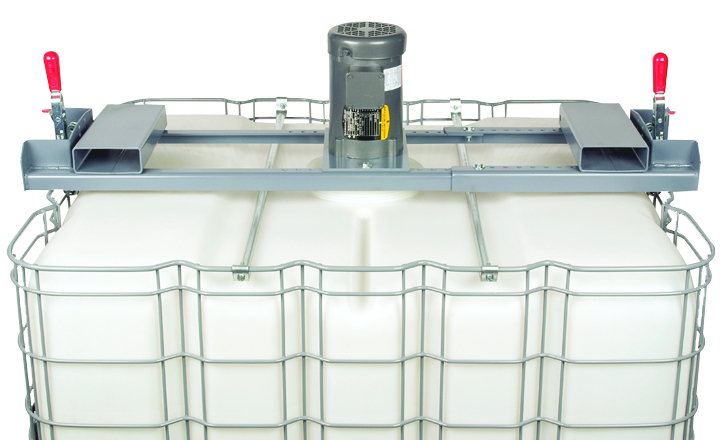

The INDCO model BGTC-200T is an electric, gear-driven, bracket mounted IBC tote mixer designed for heavier liquids. It is the most powerful standard IBC tote mixer that INDCO offers and has been successfully used for formulations with viscosity up to 3,000 cps. The heavy-duty bracket mounts to the tote cage using ergonomic toggle clamps and can be optionally provided with forklift channels or a lifting bracket for placement on the tote.

Key Takeaways

INDCO offers one of the most complete lines of industrial mixers dedicated to IBC tote mixing. Economy models and more featured deluxe products are available. As a general recommendation - direct-drive models with smaller diameter, single mixing impellers are suitable for low viscosity fluid mixing, such as those with viscosities like water. However, due to the less-than-ideal cubic tote configuration and the limitation on impeller size by the six-inch opening, higher viscosities will benefit from higher horsepower, gear-driven models with multiple folding impellers and a mounting bracket for added stability.

INDCO is your direct source for industrial mixers for all types of mixing containers. For heavy-duty mixing needs, take a look at our latest stainless steel IBC tote mixer. For more assistance with mixer selection or to customize a design for your mixing applications, contact our expert representatives or get in touch with our applications engineers at (800) 851-1049.