How to Choose Your Dispersion Blade Style

How to Choose Your Dispersion Blade Style

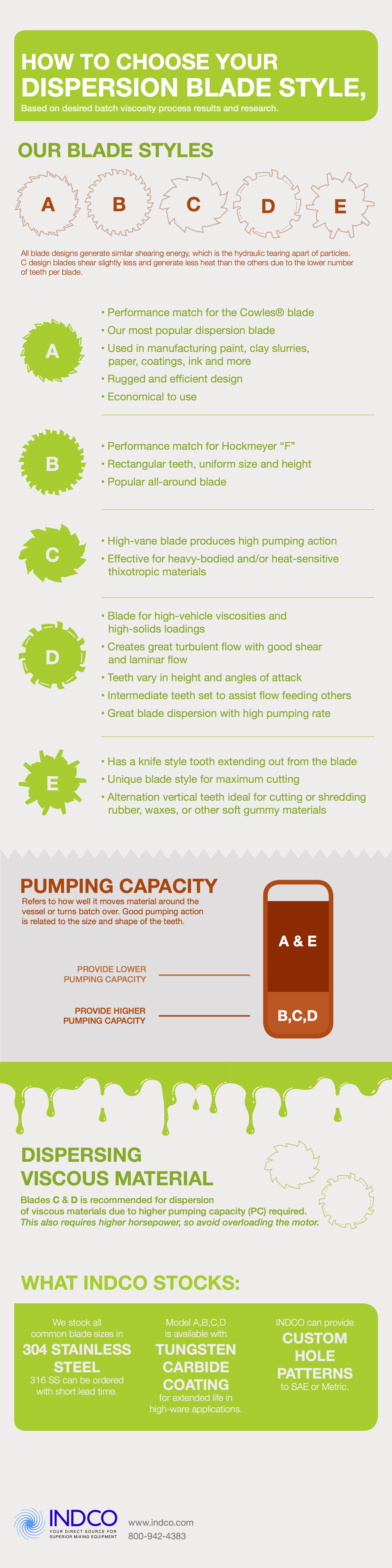

All blade designs generate similar shearing energy, which is the hydraulic tearing apart of particles. C design blades shear slightly less and generate less heat than the others due to the lower number of teeth per blade.

A.

- - Performance match for the Cowles blade

- - Our most popular dispersion blade

- - Used in manufacturing paint, clay slurries, paper, coatings, ink and more

- - Rugged and efficient design

- - Economical to use

B.

- - Performance match for Hockmeyer "F'

- - Rectangular teeth, uniform size and height

- - Popular all-around blade

C.

- - High-vane blade produces high pumping action

- - Effective for heavy-bodied and/or heat-sensitive thixotropic materials

D.

- - Blade for high vehicle viscosities and high-solids loadings

- - Creates great turbulent flow with good shear and laminar flow

- - Teeth vary in height and angles of attack

- - Intermediate teeth set to assist flow feeding others

- - Great blade dispersion with high pumping rate

E.

- - Has a knife style tooth extending out from the blade

- - Unique blade style for maximum cutting

- - Alternation vertical teeth ideal for cutting or shredding rubber, waxes, or other soft gummy materials

Pumping Capacity: Refers to how well it moves material around the vessel or turns batch over. Good pumping action is related to the size and shape of the teeth. A & E provide lower pumping capacity. B, C, and D provide higher pumping capacity.

Dispersing Viscous Material: Blades C & D are recommended for dispersion of viscous materials due to higher pumping capacity required. This also requires higher horsepower, so avoid overloading the motor.