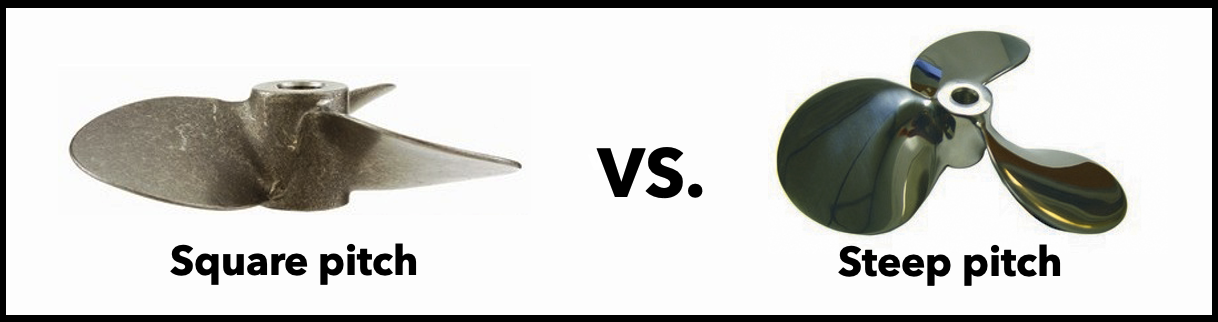

Industrial Mixing Propellers: Square Pitch vs. Steep Pitch

The marine style industrial mixing propeller has long been the impeller of choice for agitation or blending of low viscosity liquids. Cast propellers are cost effective and provide significant fluid motion per unit of power consumed. The most common design is that which is referred to as “square pitch”. The square pitch propeller has a pitch ratio of 1:1 which means for each rotation fluid is moved forward by an amount equal to its diameter. The fluid movement produced by a given impeller is often measured as a pumping rate in gallons per minute (GPM) or in tank volume turnover per minute (turns/min.). The motor rating in horsepower required to drive a propeller in a given application is determined primarily by the propeller diameter and rotational speed.

When increased flow or agitation is required there are multiple options to achieve the increase: higher speed (rpm), larger diameter impeller or alternate impeller type. Each of these change options impacts horsepower, torque and mixer critical speeds, those at which resonance occurs resulting in excessive vibration. One option available to the process operator is to utilize a “steep pitch” propeller. The steep pitch marine style propeller allows the operator to stay in the same propeller diameter but with increased fluid flow. Typically, a steep pitch propeller has a 1.5:1 pitch ratio and provides 50% more flow than the square pitch version. The tradeoff, of course, is power usage. For the benefit of increased flow at the same operating speed of the square pitch propeller, a steep pitch will require twice the horsepower to drive it. Therefore, the mixer drive motor horsepower should be evaluated for proper capacity to drive the steep pitch propeller without overheating.